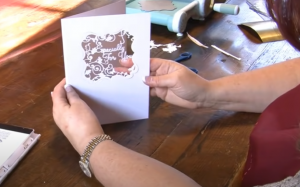

Die cutting is a process that requires the use of a specialized tool. This die, made from hardened steel, enables you to cut through materials like paper, cardboard, foam rubber and even metal! Utilizing this method can help your business produce more efficient and accurate products with greater speed than ever before.

Die cutting is a process that requires the use of a specialized tool. This die, made from hardened steel, enables you to cut through materials like paper, cardboard, foam rubber and even metal! Utilizing this method can help your business produce more efficient and accurate products with greater speed than ever before.

Die cutting stands out from other manufacturing processes due to its precision. Through the use of a powerful die-cutting press, materials can be cut with high levels of accuracy – pivotal for many production needs and applications! Companies across industries such as packaging, printing and textiles rely on die-cutting when creating custom boxes, label designs or gaskets and seals. Additionally, this tried-and-true technique is also used in making washers as well. Whatever your production requirements may be – die cutting will surely get it done quickly & precisely!

For cutting and forming materials, you have two main options: rotary die cutting or flatbed die cutting. Rotary is the perfect pick for those who need to cut larger volumes of material quickly; it’s often used in the manufacture of labels and packaging supplies. Flatbed, however, is preferred if more intricate shapes are required – despite its slower speed.

Die cutting is a highly efficient and cost-effective process that enables companies to produce large quantities of products quickly. Its versatility is unrivaled as it can be used to cut numerous materials, such as paper, cardboard, foam rubber, and even metal! Therefore die cutting offers an ideal solution for businesses looking to both reduce costs while producing various items.

Die cutting is an indispensable manufacturing process that provides precision, cost-effectiveness, and versatility. This makes it a valuable asset for businesses looking to create high-quality products in the fastest time possible while saving on costs. Its application spans across various industries, making its use ubiquitous!

When selecting a die cutting service provider, it is essential to seek out one that has established an impressive reputation in the industry. Focus on companies with proven success stories of delivering high-quality products and exceptional customer support. With such a partner, you can trust that your goods will be crafted to perfection – leaving no room for dissatisfied customers! Take your time to find the right company; when you do so, they become an invaluable asset to ensuring successful manufacturing operations. You can also read these reviews to find the perfect company for you.